Building Products: Is This the Future of Roofing

For many homeowners choosing a new roof is about selecting either clay or concrete tiles. After all these staples combine rustic and modern looks while being very durable and economical.

However, today when it comes to building products and roofing materials it is well worth keeping an open mind. A case in point is the fiber cement slate.

Fibre cement is a material that has commonly been used in exterior siding but is now available in forms that make them a viable roofing option.

Among the building products its sells, Tegral is the sole manufacturer of fiber cement roof slates in the whole of Ireland. The compound that is used to manufacture fiber cement roof slates is a combination of sand, cement, and cellulose. Very versatile to natural elements they also can cope with fire and insects.

Fibre cement has a long history as a building product. It has been used for siding buildings for more than 50 years. It is now discovering worldwide popularity as a roofing material.

There are a number of reasons for this. They include:

Long Life Spans

A roof is often replaced as a major home renovation project. In many cases, the motivation is to deal with a requirement to repair what was there before on an as-needed basis.

It is not often a proactive way to boost the appeal of how a property looks or to change the way your house appears.

When a roof begins to leak, sag or come apart in strong winds, a new surface is called for. A new roof is invariably a mandatory fix rather than the average person’s idea of a luxury addition. As a result, the most common sentiment is to resurface the top of the house as little as possible.

This is where fiber cement slates become appealing. They come with a long warranty and have life expectancies that last for decades beyond 50 years.

Stand Up to the Elements

The reason why some roofing materials are guaranteed for much shorter spans and some even fail before the warranty has expired could be due to a number of factors.

Poor installation including improper fastenings or skimping on flashings, drip edges, and weather guards can have a very negative effect on the length of time a roof can last.

Another determining factor could be the weather that the roof has to endure depending on climate and where the house is built.

A huge advantage of fiber cement slates is that they are durable and extremely resistant to the elements even as the material gets older. Fibre cement’s internal makeup is resistant to moisture and salt. This makes it a great material to use for the roof os a waterfront property.

Mildew and mold spores do not tend to feed on fiber cement and the slates don’t buckle and swell up when exposed to heat. Nor do insects feed on fiber cement as they tend to do with other roofing options.

Lightweight

Fibre cement slates appear to share many of the same properties as concrete or clay tiles, which are two very popular roofing material options.

However, fiber cement slates have a huge advantage over concrete tiles – they are many times lighter. A home roofed with any of the conventional materials – clay, concrete, stone, and slate – tend to require extra structural supports in the joists to take the added weight. Fibre cement slates do not.

Range of Colour Options

Fibre cement slates can be bought already factory-painted, which means they can come with thick, secure coatings for added protection. Pieces can also be primed so that individual homeowners can paint them themselves, saving some of the installation costs.

Another benefit of this product’s cement compound is that it is able to be repainted with acrylic to achieve even more enhanced curb appeal without the need to install yet another whole roof.

Fire Resistant

Because fiber cement roofing is a blend of cement, sand, and cellulose, it is fire resistant.

The material has a fire retardant rating of almost 90%. Combined with fiber cement siding this could restrict flames spreading much better than other more flammable roofing materials.

Stylish Options

Modern methods of manufacturing fiber cement roofing means that many styles can be created using the material. For example, fiber cement siding can come in architectural panels, lap siding or shingles and shakes. The material can also emulate a wood, cedar, stucco or smooth appearance.

Fibre cement roofing is versatile. It can be distributed as corrugated sheets and shingles/shakes or panels. This variety of styles means the material is viable for roofing both residential and commercial projects as well as sheds, barns, garages, and other outbuildings.

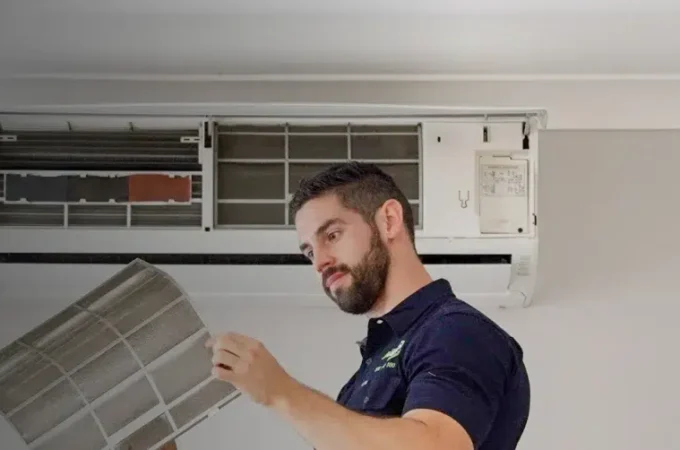

Handling and Installation

There is a myth that fiber cement slates can be difficult to work with. It’s true that cutting with normal tools can create a large amount of dust and installers must beware allowing the center of a long piece of slate bow or it can snap.

However, the way to dissipate debris creation is to use special shears that cut more slowly and virtually eliminate all dust creation. Circular saws with dust collectors also create a much cleaner environment.

To tackle difficulties when installing layers, there are guides available. These can be set and are capable of holding pieces in place making one-person installation possible.

Cost

Fibre cement comes in sheets that make installation a more efficient job. Around 1200mm can be covered by 3000mm with each piece. Ceramic and clay tiles measure are around 150mm X 350mm each. This means approximately 16 of these would be needed to fill the area of one fiber cement sheet.

Installing fiber cement over this sort of area would cost about £4 less than ceramic tiles. This amounts to a substantial saving over a complete project.

Return On Investment

Fibre cement offers durability, style, workability, and cost savings. The material is also energy-efficient and environmentally friendly.

The year-on-year ROI is boosted by the expected lifespan of fiber cement roof materials. In addition, installation can enhance the appeal of a home to any future buyers.

Installing fiber cement siding returns around 85% of any initial investment.